Working from our dedicated clean room facilities in Adelaide, South Australia, our team of highly skilled technicians hand-swage, wind and package a broad range of premium quality, absorbable and non-absorbable sutures that comply with and often exceed the strict regulatory and legal standards relevant to each location where Dynek sutures are sold.

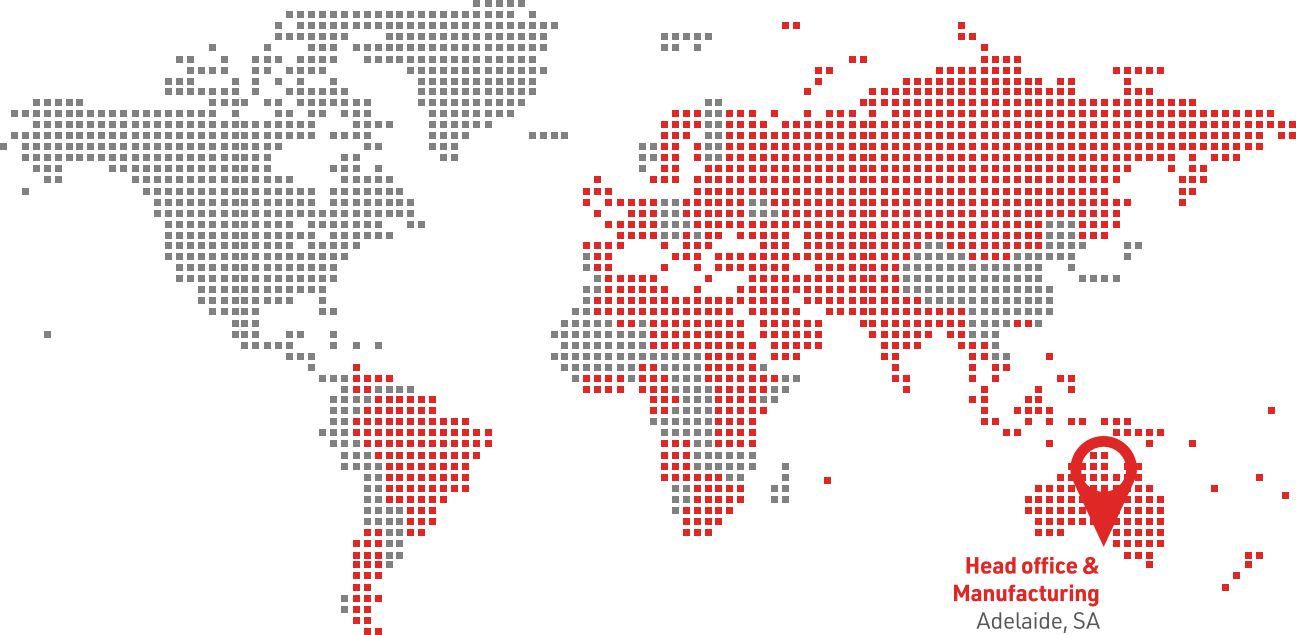

Our singular focus and understanding of the unique needs of the medical profession are the foundations of customer-centred and consultative relationships we foster with our customers in Australia and around the world. These relationships, along with the excellence of our products, are the key to our reputation as a world class manufacturer and supplier of surgical products.

When purchasing sutures, for excellent patient outcomes, insist on the technical quality and surgical excellence of Australian made Dynek sutures.

The Dynek team is totally committed to the successful implementation and maintenance of Total Quality Control. Quality goals are achieved by the development and constant refining of Standard Operating Procedures, thorough training, and continuous personnel education.

Dynek sutures are manufactured to Standard ISO 13485.

Dynek is a company in which Total Quality Control is placed above all other considerations, a company whose primary task is absolute customer satisfaction and confidence in a product manufactured with pride under the Dynek trademark.

Briefly, Dynek’s Quality Assurance Program is executed by:

Tell us what you need

– Material, USP size, and thread length.

– Needle type and size.

OR

Tell us what you’re currently using

– e.g. product code

We can also custom make sutures. Ask us today.

Buy direct now